Since the beginning 2021, I’ve pursued a personal project that combines my love of outdoor sports and interest in machine design. The winch pulls skateboarders, skiers, and other riders. This page will be updated as the winch is tested and improved throughout Spring 2023.

Goals

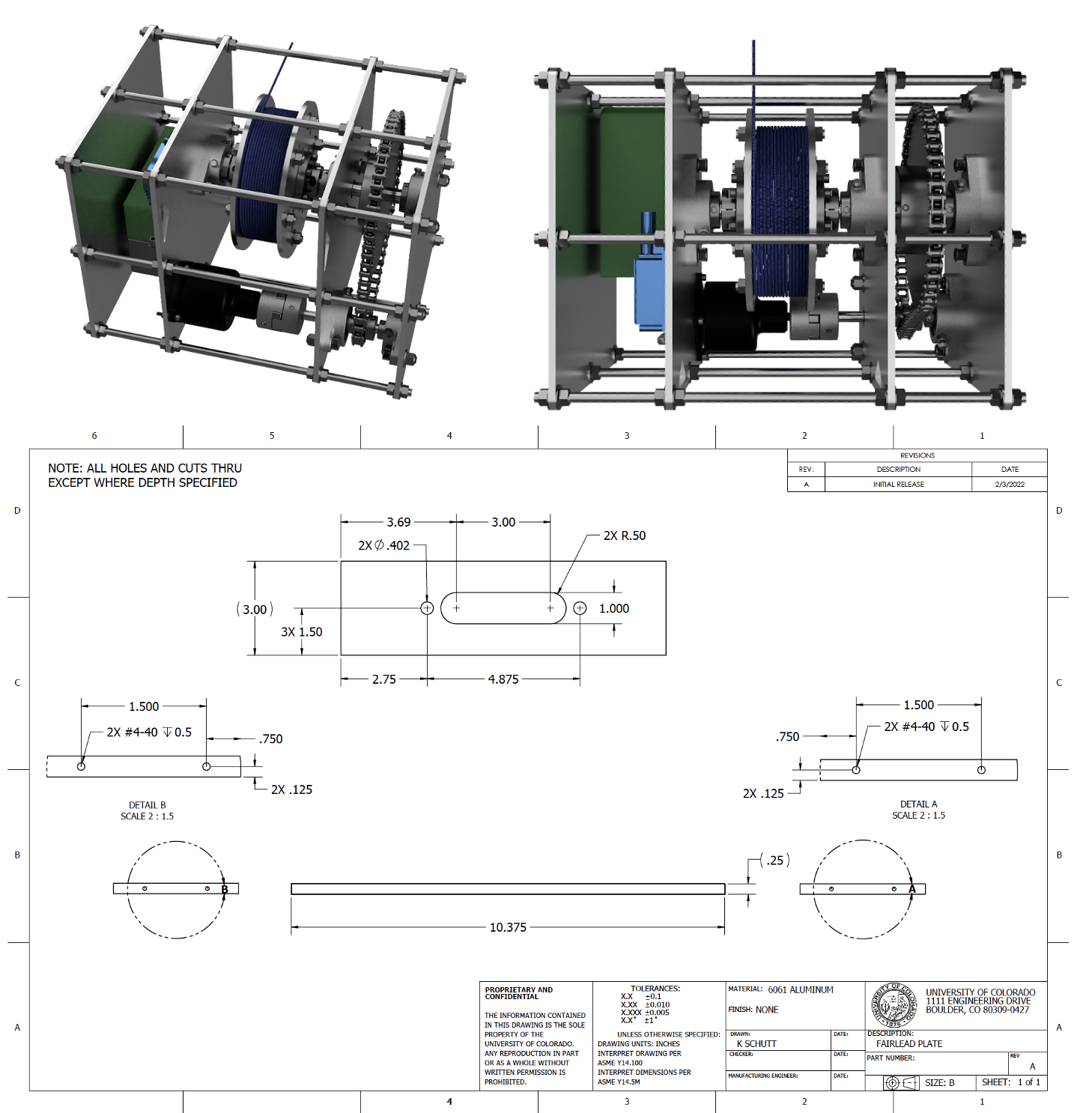

Design and build an electric winch consisting of a DC motor coupled to a chain drive and a reel to pull a rider on skateboards, skis, wakeboards, etc.

Calculations

To begin designing the winch, I had to understand what forces the winch and its pulling mechanisms would see. I had just finished the Drill Powered Bicycle project, so I envisioned a motor and a chain drive pulling a wheel of rope.

Estimated the frictional forces that would have to be overcome to pull a ~200 lb rider on waxed skis in the snow

Wrote a MATLAB scripts to play with the many combinations of motors, gear ratios, and reel diameters that could achieve a rider speed of 25 mph

Component Selection

Based on calculations, decided on a reel diameter of ~8 in, gear ratio of 5:1

Selected a brushless DC motor and accompanying batteries and ESC based on operating voltages and current

Required selecting shafts, keys, couplers, bearings, sprockets, chain

Performed more Matlab calculations and ANSYS simulations

Ensure shaft diameters were wide enough

Plates thick enough

Keys and set screws wouldn’t shear

CAD

Utilized Fusion360 to model the winch and ensure that components fit together with enough clearance

Made engineering drawings and DXF files for manufacturing

Funding

Drafted a grant request and secured $700 in funding from CU Mechanical Engineering department

Ensured access to campus machine shop

Collaborated with campus machinists to create engineering drawings

Manufacturing

Soldered 8 and 10 gauge wire and XT90 connectors to create custom series connector for batteries

Manufactured aluminum plates and spacers

Waterjet cut initial standoff and reel plate designs

Utilized mill to add chain-tensioning slots and fabricate fairlead plate

Drilled and tapped holes for chosen screws

Cut standoffs and shafts, finished shafts on lathe

Polished and deburred

Controls

Programmed and manufactured remote to control winch operation with Adafruit Feather Transceiver breakout boards and 3D printed casing